Why Do Chemicals with the Same Name Produce Different Results in Practice?

In industrial manufacturing, many enterprises encounter a phenomenon that appears counterintuitive at first glance: chemicals bearing the same name, the same molecular formula, the same labeled concentration, and even identical Certificates of Analysis (COA) can nevertheless yield markedly different outcomes when applied in production processes. Why Do Chemicals with the Same Name Produce Different Results in Practice?

Some batches perform consistently and stably over extended periods.

Others operate well initially but gradually exhibit increasing deviations.

In certain cases, product defects arise without any clearly traceable cause.

This is not an isolated incident. Rather, it represents a systemic issue within the B2B chemical industry.

Why, then, do chemicals with the same name lead to different operational results?

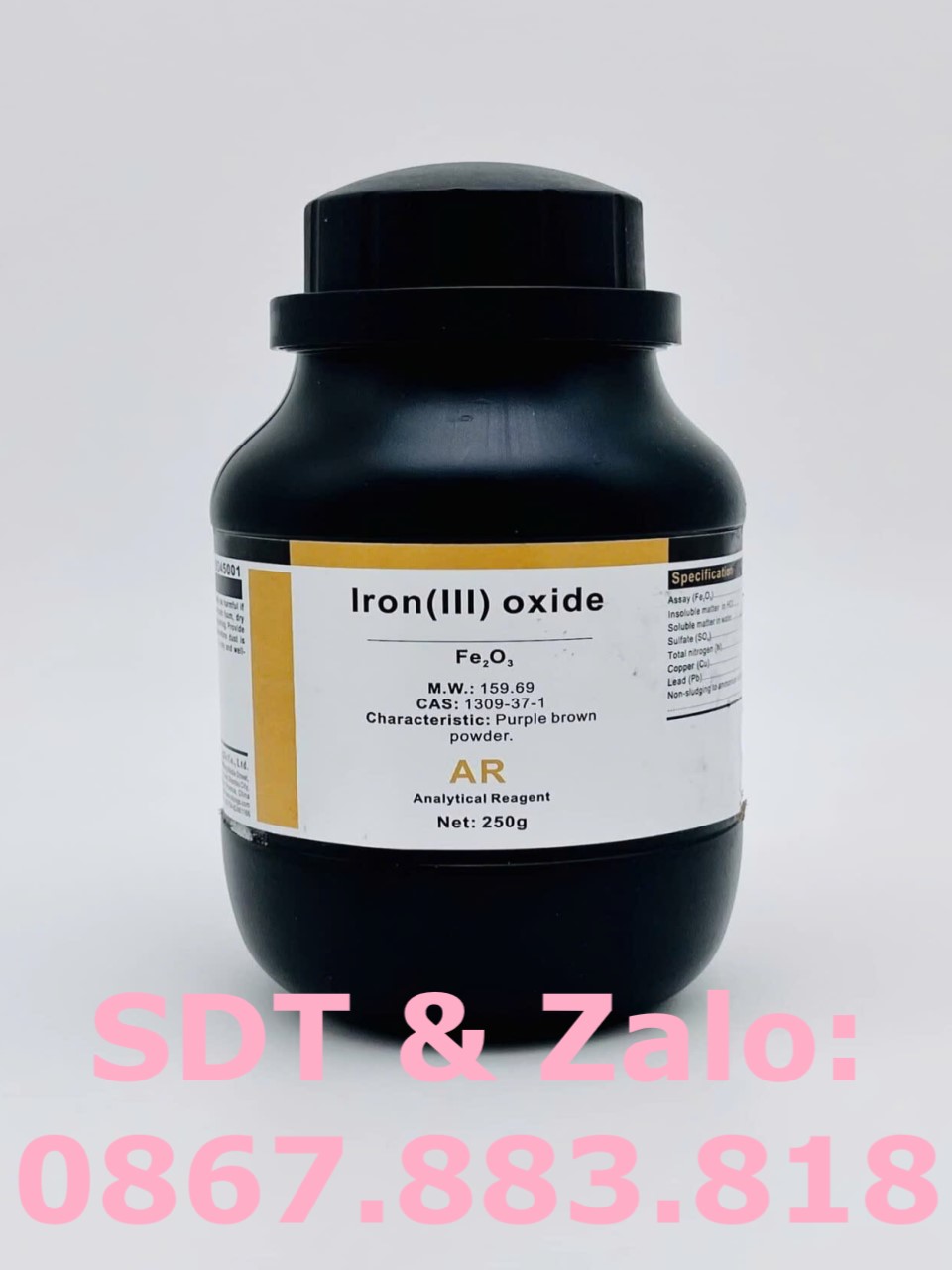

1. Purity and the “1% Impurity Trap”

Most industrial-grade chemicals exhibit purity levels ranging from 98% to 99%.

The critical differences often lie within the remaining 1%.

Antagonistic impurities

In organic and catalytic reactions, trace amounts (ppm-level) of heavy metals or foreign ionic species can act as catalyst poisons. These impurities may suppress reaction rates, halt reactions entirely, or promote the formation of undesired by-products.

Example:

Two sodium hydroxide (NaOH) products may both be labeled as 99% purity. However, NaOH produced via membrane cell technology typically contains significantly lower chloride ion (Cl⁻) concentrations than material produced using older diaphragm processes.

In electroplating or electronics manufacturing, excess Cl⁻ ions are a primary cause of latent corrosion and long-term product failure.

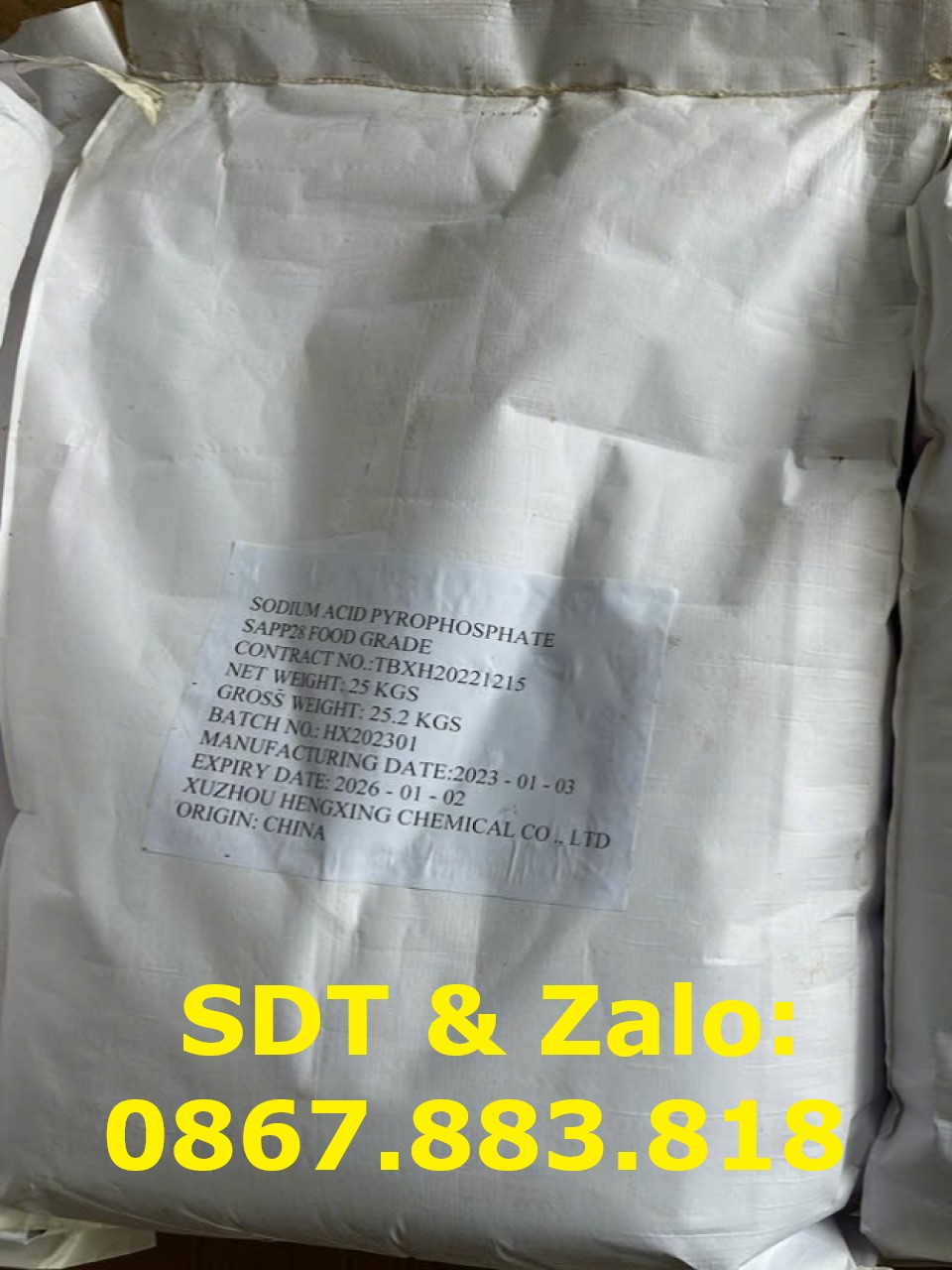

2. Identical Chemical Names Do Not Imply Equivalent Functional Quality

A chemical name and molecular formula define only the fundamental chemical identity of a substance.

They do not fully describe its physical state, effective purity, or behavior within a specific process environment.

Two batches of the same chemical may differ substantially in:

-

Trace impurity profiles

-

Isomer ratios or hydration states

-

Particle size distribution or crystalline morphology

-

Adsorbed moisture accumulated during storage

These differences are often not fully disclosed on product labels or basic specifications, yet they exert a direct influence on reaction kinetics and process stability.

Furthermore, a single chemical can be synthesized via multiple production pathways, each leaving behind a distinct chemical fingerprint.

-

Petrochemical-based routes: Typically offer high consistency but may introduce aromatic hydrocarbon residues.

-

Bio-based routes: Environmentally favorable, yet often contain complex organic impurities that may induce discoloration or off-odors in finished products.

3. Identical COAs Do Not Guarantee Identical Chemical Behavior

A Certificate of Analysis (COA) represents analytical results obtained at a specific moment in time.

It reflects the properties of a sampled portion, not necessarily the entire lifecycle behavior of a batch.

In practice, two batches with similar COAs may behave differently due to:

-

Non-representative sampling

-

Variations in storage conditions before and after sampling

-

Chemical or physical changes during prolonged storage

A COA confirms compliance at the time of testing, but it does not ensure long-term stability under continuous production conditions.

4. Inter-Batch Consistency Is Critical—Yet Often Overlooked

In industrial production, success does not depend on a single compliant batch.

It depends on multiple consecutive batches exhibiting consistent behavior under identical operating conditions.

Inter-batch consistency is governed by:

-

Raw material sourcing strategies

-

Synthesis or purification processes

-

Packaging and storage control

-

Statistical control of process variability

When these factors are inadequately managed, minor deviations in individual batches can accumulate into significant process instability.

5. Chemical Variability Alters Both Chemical Reactions and Physical Phenomena

In many applications, chemicals influence not only reaction chemistry but also physical system behavior, including:

-

Dissolution rate

-

Dispersion efficiency

-

System viscosity

-

Stability of solutions or emulsions

Small changes in particle size, moisture content, or impurity composition can significantly alter these properties, ultimately affecting the entire production process.

6. The Greatest Risk Lies Not in the Chemical, but in Supplier Selection

In many cases, the root cause of process failure is not the chemical itself, but the level of control and accountability exercised by the supplier.

A supplier that merely sells products—without batch stability control, traceability documentation, or a defined incident response protocol—effectively transfers all operational risk to the end user.

7. How Can Enterprises Reduce Risk?

Before procuring industrial chemicals, organizations should address several systemic questions:

-

How is inter-batch consistency controlled and documented?

-

Are traceability records and storage conditions clearly defined?

-

When deviations occur, how are corrective actions and responsibilities assigned?

These considerations are far more critical than price comparisons alone.

Conclusion

In the B2B chemical industry, identical names do not equate to identical functional value.

Minor differences in raw materials, production routes, and quality control systems can lead to substantial variations in manufacturing outcomes.

Organizations that recognize this reality prioritize stability, traceability, and supplier accountability, rather than relying solely on nominal specifications and cost.

Technical Support and Industry Insights from KDC CHEMICAL

For professional insights and accurate technical information within the chemical industry, KDC CHEMICAL provides timely and reliable support to industrial partners.

For further information, please visit kdcchemical.vn or contact our technical hotline at +84 867 883 818.