What Is MSDS – A Safety Document or Merely a Formality?

In industrial chemical management, the MSDS (Material Safety Data Sheet) is widely regarded as a “mandatory document.” In practice, however, MSDSs are often merely archived in files, stored in binders, or attached to procurement emails, while being rarely read thoroughly, critically analyzed, or properly implemented in daily operations. This reality raises a fundamental question: Is the MSDS truly a core safety document, or has it been reduced to a procedural formality? What Is MSDS – A Safety Document or Merely a Formality?

This article examines the true nature of the MS DS, explains why many enterprises fail to read and use it correctly, and analyzes the hidden operational risks that arise when MSDSs are treated solely as compliance paperwork.

DS, explains why many enterprises fail to read and use it correctly, and analyzes the hidden operational risks that arise when MSDSs are treated solely as compliance paperwork.

1. What Is MSDS – Understanding It Correctly from the Start

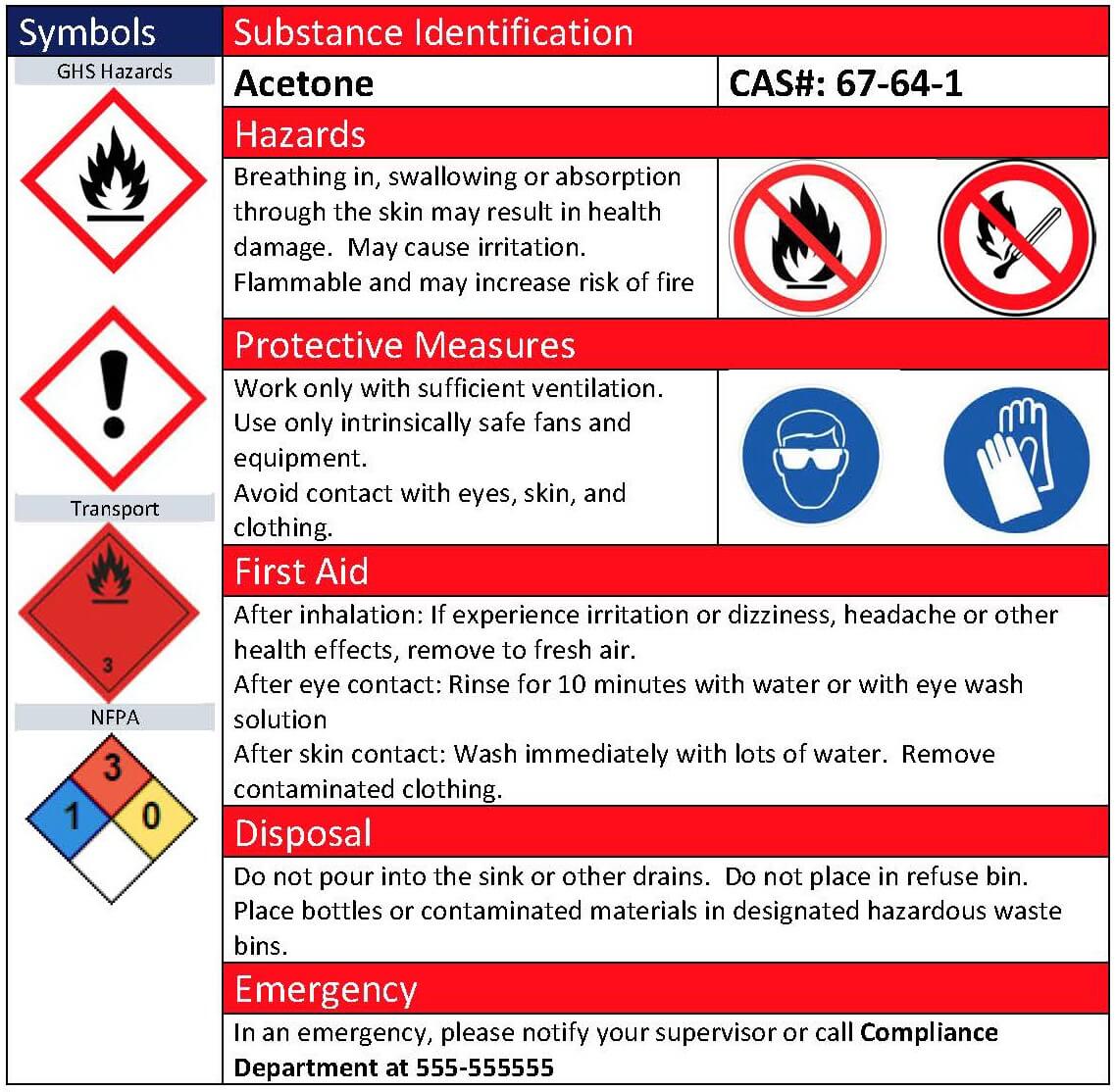

By definition, an MSDS is a document prepared by a chemical manufacturer or supplier to provide safety, health, and environmental information related to a specific chemical under reasonably foreseeable conditions of use. It is a technical document containing highly detailed data on physical and chemical properties, hazard characteristics, and emergency response measures associated with a chemical substance.

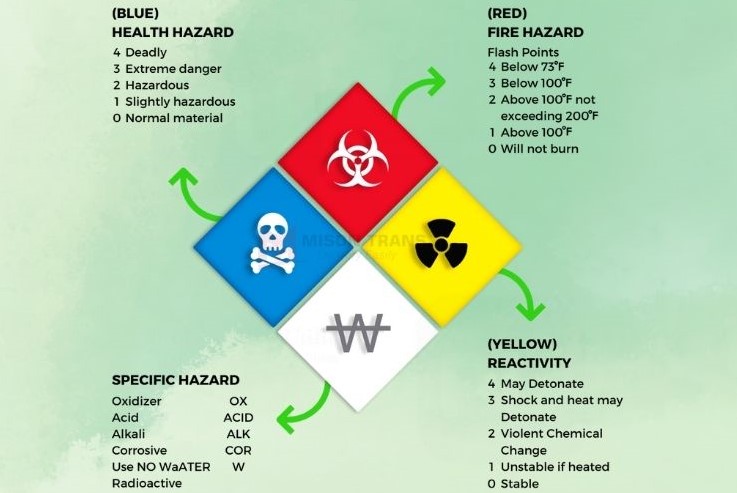

Under the GHS (Globally Harmonized System), a compliant Safety Data Sheet (SDS) must consist of 16 standardized sections.

A typical MSDS/SDS includes:

-

Identification of the substance and supplier

-

Composition and information on hazardous ingredients

-

Hazard identification

-

First-aid measures

-

Firefighting measures

-

Accidental release measures

-

Handling and storage

-

Exposure controls and personal protective equipment (PPE)

-

Physical and chemical properties

-

Stability and reactivity

-

Toxicological information

-

Ecological information

13–16. Transport, regulatory, and other relevant information

Therefore, the MSDS is not a quality specification, but a risk management document.

Why distinguish between MSDS and SDS?

Although the terms are often used interchangeably, SDS is the modern, GHS-standardized version with a globally unified 16-section structure. Using SDS allows procurement and EHS teams to compare information across suppliers consistently, avoiding confusion caused by non-standard or self-defined formats.

2. What MSDS Is Not

One major reason MSDSs are misunderstood is that organizations often assign them roles they were never designed to fulfill.

An MSDS is not:

-

A certificate of chemical quality

-

A guarantee of reaction performance or product functionality

-

A universal assurance of safety under all operating conditions

-

A detailed production process manual

-

A substitute for internal risk assessment

In essence, the MSDS provides baseline hazard information; whether a chemical is used safely depends on how an enterprise interprets and applies that information in real operational contexts.

3. The Role of MSDS within an Organization

To understand why MSDS is not merely a formality, it is necessary to examine its impact on key departments.

For QA/QC and Production Teams

The MSDS provides technical parameters such as purity-related information, boiling point, flash point, and material compatibility.

-

Quality control: Helps QA identify whether impurities may pose risks to production lines or end products.

-

Process stability: Enables engineers to anticipate hazardous reactions, fire risks, or corrosion-related equipment failures.

For EHS (Environment, Health, and Safety)

The MSDS serves as a foundational document for risk matrix development. Section 8 (Exposure Controls / PPE) guides EHS teams in selecting appropriate respirators, chemical-resistant gloves, and ventilation systems. Without a reliable MSDS, workers are effectively operating in a “blind” safety environment.

For Procurement Departments

The MSDS functions as a supplier evaluation tool. Reputable suppliers provide transparent, up-to-date MSDS documentation. In contrast, vague or inconsistent MSDSs often indicate low-quality sources, legal exposure, and potential hidden costs arising from incident management.

4. Why Do Many Enterprises Fail to Read MSDS?

4.1 MSDS Viewed as a Compliance Requirement Only

In many organizations, MSDSs are requested solely for:

-

ISO / FSSC / GMP audits

-

Safety and environmental inspections

-

Mandatory procurement documentation

When MSDSs are treated as “paperwork to complete,” in-depth analysis becomes unnecessary.

4.2 Technical Language Barriers

MSDSs contain:

-

Chemical terminology

-

GHS classifications

-

Toxicological indices (LD₅₀, LC₅₀)

-

Reaction and decomposition conditions

Without a chemistry or EHS background, many procurement or operational staff lack the ability to interpret these details, leading to complete neglect.

4.3 The Misconception That “COA Is Sufficient”

A common assumption is:

“If the chemical meets COA specifications, the MSDS is just for filing.”

In reality, COA and MSDS serve entirely different purposes:

-

COA → batch quality conformity

-

MSDS → safety, health, and environmental risk

Confusing these documents inevitably results in MSDS being undervalued.

5. Three Critical MSDS Sections Commonly Overlooked

Rather than focusing only on the chemical name, technical teams should prioritize the following sections:

Sections 9 & 10: Physical Properties and Chemical Stability

These sections define appropriate storage conditions. For example, chemicals with low auto-ignition temperatures or moisture sensitivity require specialized storage with strict temperature and humidity control.

Section 14: Transport Information

This is crucial for logistics. UN numbers and packing groups determine whether chemicals can be transported by air, sea, or require specialized vehicles. Errors here may lead to shipment detention or severe administrative penalties.

Section 15: Regulatory Information

This section allows enterprises to verify compliance with national chemical regulations, including restricted chemicals, conditional business licenses, or mandatory chemical incident response planning.

6. Real Risks of Not Reading MSDS

6.1 Occupational Safety Risks

Failure to understand MSDS leads to:

-

Inappropriate PPE selection

-

Incorrect spill response

-

Delayed emergency reactions

-

Chronic exposure to hazardous substances

Many accidents occur not because chemicals are inherently dangerous, but because known hazards documented in the MSDS were ignored.

6.2 Chemical Interaction and Storage Risks

The “Stability and Reactivity” section is frequently overlooked, resulting in:

-

Incompatible chemical co-storage

-

Unintended reactions during mixing

-

Thermal decomposition or toxic gas release

-

Reduced lifespan of chemicals and equipment

6.3 Legal and Reputational Risks

In chemical-related incidents, authorities often ask:

“Did the company read and implement the MSDS?”

Even when MSDS documentation exists, failure to apply it properly does not exempt an enterprise from legal liability.

7. MSDS and Low-Cost Chemicals: An Overlooked Connection

Low-cost chemicals are often associated with:

-

Superficial or copied MSDS documents

-

Outdated GHS classifications

-

Data that does not reflect real operating conditions

-

Incomplete toxicological information

An MSDS that merely “contains 16 sections” is not necessarily reliable.

This explains why chemicals cannot be procured using consumer-goods logic, even when both COA and MSDS appear complete on paper.

8. How to Use MSDS Properly

Step 1: Read MSDS with an Operational Mindset

Focus on Sections 2, 7, 8, and 10, especially storage conditions, PPE requirements, and chemical compatibility.

Step 2: Convert MSDS into Internal Procedures

MSDS is only effective when translated into SOPs, used in operator training, and displayed at points of use.

Step 3: Evaluate Suppliers Through MSDS

Professional suppliers provide updated MSDSs, clearly explain hazards, and support application-specific risk assessments.

Conclusion

The MSDS is not a procedural formality—but it becomes one if enterprises merely archive it without reading, understanding, and applying its content. In modern chemical management, MSDS is a cornerstone of operational safety, not an appendix to procurement files. Enterprises seeking sustainable growth must treat MSDS as an integral component of their technical system, closely linked to people, equipment, and processes, rather than as a document kept solely to “meet requirements.”

For expert consultation and accurate information on the chemical industry, KDCCHEMICAL provides fast and reliable support. Visit kdcchemical.vn or contact our hotline at +84 867 883 818.