Why COA Cannot Replace Technical Evaluation

Why COA Cannot Replace Technical Evaluation

Why COA Cannot Replace Technical Evaluation?

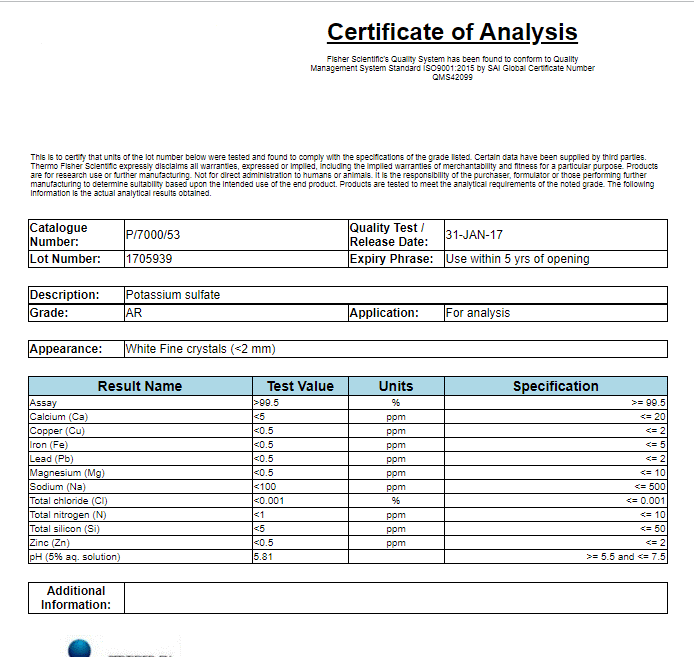

In B2B chemical trading, the Certificate of Analysis (COA) is almost a mandatory document.

Many buyers consider COA as the “final proof of quality.”

However, in real technical practice, COA is not sufficient and can never replace proper technical evaluation.

Misunderstanding the role of COA can lead to serious risks:

-

Unstable product quality

-

Process performance deviation

-

Complaints, returns, and even safety incidents

This article explains why COA is only an input dataset — not a technical conclusion — especially in the industrial chemical sector.

1. What Is COA? Understanding Its True Nature

A COA is a manufacturer’s analytical certificate that shows:

-

Certain physicochemical parameters tested

-

Measured values at a specific time

-

Based on a representative sample

The Chemical Nature of COA

COA reflects static analytical results, not:

-

Chemical behavior in dynamic systems

-

Interaction with other substances

-

Real operating conditions such as temperature, pH, shear force, and reaction time

In other words, COA answers the question:

“Does this sample meet parameter X in the laboratory?”

But it does not answer:

“Will this chemical perform well in your actual production system?”

Fundamentally, COA only represents laboratory test results under controlled conditions at a given moment.

The Trap of “Good-Looking Numbers”

Many buyers focus only on the Assay value.

For example: A batch of Acetic Acid with an assay of 99.8% looks very safe.

However, COA rarely specifies what the remaining 0.2% actually contains.

-

If the 0.2% is water, your system may tolerate it.

-

If the 0.2% consists of heavy metals or organic ring compounds (from raw material impurities), it can poison catalysts in your production process, causing massive financial losses.

2. The Inherent Technical Limitations of COA

2.1. COA Does Not Reflect the Full Composition

In many industrial chemicals:

-

Additives, trace impurities, and stabilizers are not declared

-

COA only lists the main commercial parameters

For example:

-

Two batches both show 99% active content

-

But use different stabilizers → leading to different reaction stability

COA is not responsible for describing such differences.

Particle Size Distribution (PSD)

For powder chemicals (such as TiO₂ or CaCO₃), COA may show very high purity.

However, if PSD is inconsistent, dispersion in solvents becomes poor, causing agglomeration.

This directly affects:

-

Gloss and durability of coatings

-

Tensile strength of plastics

Presence of Isomers

In organic chemistry, compounds with the same molecular formula but different structures (isomers) exhibit completely different chemical activities.

Typical COAs only measure total functional group content without separating isomer ratios.

This can lead to uncontrolled side reactions in real production.

Stability Over Time

COA is issued when goods leave the factory.

But chemicals are “living entities.”

During transportation — especially ocean shipping — temperature and humidity can change parameters such as:

-

Acid value

-

Peroxide value

Only real technical inspection at the buyer’s warehouse reflects the actual quality before charging into reactors.

2.2. COA Does Not Simulate Real Operating Conditions

COA analysis is conducted under:

-

Standard temperature

-

Ideal laboratory environment

-

No contamination from production systems

In real production:

-

Chemicals face heat, shear, oxidation, metal ions

-

Side reactions may occur

COA cannot predict these phenomena.

2.3. COA Does Not Evaluate Process Performance

COA does not provide:

-

Reaction rate

-

Long-term stability

-

Real consumption efficiency

In engineering, process performance is the real decision factor.

COA does not measure performance.

3. What Is Technical Evaluation?

3.1. Technical Evaluation Is a Process, Not a Document

Technical evaluation includes:

-

Understanding chemical reaction mechanisms

-

Matching with actual process technology

-

Pilot or semi-industrial testing

-

Long-term stability evaluation

This is a dynamic process, completely different from COA.

3.2. Chemical Perspective: Same COA, Different Mechanisms

Two products may share similar COA values but differ in:

-

Particle size

-

Crystal form

-

Dispersion behavior

These directly affect:

-

Dissolution rate

-

Reaction efficiency

-

System stability

COA does not describe microstructure.

4. The EUV Framework in B2B Chemical Evaluation

4.1. E – Engineering (Mechanism & Technology)

Key questions:

-

What is the reaction mechanism?

-

Are there by-products?

-

What are the activation conditions?

COA does not explain mechanisms.

4.2. U – Usage (Real Application)

Must evaluate:

-

Optimal dosage

-

Safety limits

-

Compatibility with existing systems

COA does not guide application.

4.3. V – Value (Business Impact)

Value is not on paper — it lies in:

-

Production efficiency

-

Defect reduction

-

Total lifecycle cost

COA does not measure economic value.

5. Risks of Using COA as a Substitute for Technical Evaluation

-

Choosing the wrong product even when COA “meets specs”

-

Process failures during scale-up

-

Blind reliance on documents instead of validation

-

Disputes between buyers and suppliers

In technical incidents, COA is rarely strong enough evidence.

6. The Proper Role of COA in the Decision Chain

COA is not useless, but should only be used to:

-

Verify batch conformity with initial specifications

-

Quickly compare suppliers

-

Maintain traceability records

COA is a necessary condition, not a sufficient condition.

Conclusion

COA is an analytical document — not a technical evaluation.

In the chemical industry, where mechanisms, conditions, and interactions determine outcomes, technical evaluation is the core decision factor.

Professional chemical trading companies must:

-

Read COA with engineering thinking

-

Combine testing with process analysis

-

Prioritize real performance over paper specifications

For more professional chemical industry insights, connect with KDCCHEMICAL

For expert consultation and accurate information on the chemical industry, KDCCHEMICAL provides fast and reliable support. Visit kdcchemical.vn or contact our hotline at +84 867 883 818.