The Trap of Cheap Chemicals:5 Questions to Avoid Costly Chemical Mistakes

In the industrial chemical industry, “cheap price” is often considered a competitive advantage.

However, for engineers and professional buyers, price is rarely an independent variable. It is always the result of cost-cutting somewhere along the chain of synthesis – purification – control – responsibility. 5 Questions to Avoid Costly Chemical Mistakes

The most dangerous problem is not buying low-quality chemicals by mistake.

The real danger is that a company unintentionally undervalues its own production system by selecting chemicals based on price alone.

In industrial chemistry, there is no such thing as a “cheap chemical.” There are only hidden costs.

Below are five technical questions that must be asked before purchasing any industrial chemical.

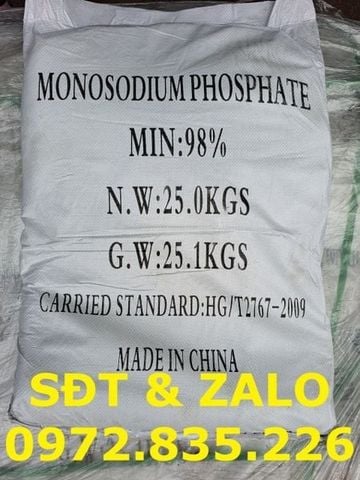

Question 1: What is the real purity — and how stable is it?

On quotations, you often see familiar numbers:

98%, 99%, 99.5%.

But in industrial chemistry, the remaining 1.5% is what determines the real risk.

From a chemical perspective

An industrial chemical always contains impurities such as:

-

Heavy metals: Fe, Cu, Pb

-

Foreign ions: Cl⁻, SO₄²⁻

-

Unreacted isomers

-

Residual solvents or intermediates

These impurities can:

-

Act as unwanted catalysts

-

Distort reaction kinetics

-

Disrupt phase equilibrium

-

Cause uncontrolled precipitation or polymerization

In coatings, inks, and textile dyeing, just a few ppm of heavy metal ions can already cause:

-

Color shift

-

Resin precipitation

-

Deactivation of leveling additives

The questions you must ask

-

How is this purity measured?

-

Is batch-to-batch repeatability controlled?

-

Is there a trace impurity analysis report?

This is the most basic — and the most important — question. In chemistry, the concept of “equivalent” is often misunderstood.

Chemical reasoning example

Suppose you purchase 98% NaOH instead of 99%. That missing 1% is typically Na₂CO₃, NaCl, or heavy metals such as Fe or Pb. These impurities are not inert.

In cosmetics or pharmaceutical production, even a few ppm of Fe³⁺ ions can catalyze oxidation reactions, causing discoloration or odor development after only one month of storage.

Consequence:

You may need to use more chemicals to compensate for lower active content, or add extra stabilizers to neutralize impurities.

Question 2: Is this product stable between batches?

In production, stability is more important than peak specifications.

A chemical with 98.5% purity and ±0.1% variation is far better than a 99.5% product fluctuating ±1%.

From an engineering standpoint

Batch inconsistency leads to:

-

Actual concentration deviation

-

Reaction rate fluctuations

-

Viscosity and density variation

-

Freezing and boiling point drift

Consequences

-

Continuous process recalibration

-

Increased dosage to compensate for purity loss

-

Loss of output quality control

The questions you must ask

-

How is batch-to-batch consistency controlled?

-

Is there SPC (Statistical Process Control) data?

-

Can raw material sources be traced?

Cheap chemicals are cheap precisely because this control is missing.

They often come from factories with weak QC systems. The first batch may be excellent, but the next batch may show viscosity or density deviations.

Process analysis

Modern automated production systems rely on calibrated parameters.

If pH or active concentration fluctuates, sensors feed incorrect signals to the PLC, causing improper compensation and chemical “overshoot” reactions.

The hidden trap

Low-cost suppliers rarely maintain historical quality data. Sudden batch variation is a silent killer of product stability.

Question 3: How does this chemical interact with your equipment?

A chemical does not only affect the product. It directly affects your fixed assets.

From a chemical–materials perspective

Key factors to evaluate:

-

pH and corrosion potential

-

Inorganic salt scaling tendency

-

Unwanted polymerization

-

Solubility and recrystallization behavior

Typical “system destruction” process

Stage 1 – Corrosion and scaling

Impurities and unstable pH accelerate corrosion of tanks, pipelines, and agitators.

Stage 2 – Sensor distortion

Foreign ions alter conductivity and refractive index, sending false signals to the PLC.

Stage 3 – Filtration blockage

Insoluble components clog membranes and nozzles, increasing downtime.

The questions you must ask

-

Is the chemical compatible with stainless steel, plastics, and elastomers?

-

Does it cause secondary crystallization?

-

Are there corrosion or fouling reports?

Question 4: What is the Total Cost of Ownership (TCO)?

Purchase price is only the first layer of cost.

In industrial chemistry, every chemical carries three layers of cost:

-

Visible cost: price per kg or per ton

-

Operating cost: efficiency, dosage, losses

-

Risk cost: downtime, reprocessing, legal liability

Cheap chemicals are usually cheap only in the first layer.

Operational impact

-

1–3% reduction in reaction efficiency

-

Increased energy consumption

-

Faster equipment aging

-

Higher maintenance frequency

These are hidden costs that never appear on quotations.

The questions you must ask

-

What is the actual consumption rate?

-

What is the conversion efficiency?

-

How much does the reject rate increase?

Question 5: Is the supplier selling chemicals — or selling responsibility?

In B2B chemicals, low price is not an advantage.

Stability is the real advantage.

Professional suppliers sell:

-

Batch stability

-

Clear technical documentation

-

Troubleshooting support

-

Full process traceability

Low-cost suppliers usually:

-

Sell once

-

Sell no responsibility

-

Sell no technical assurance

The questions you must ask

-

Is there a technical support team?

-

Is there a long-term quality commitment?

-

Are they willing to provide samples and trial runs?

When a company undervalues itself

A production system is designed with:

-

Engineers

-

SOPs

-

Quality standards

When that system uses chemicals only because they are “a few percent cheaper,” the company is effectively saying:

“Our production system is not worth protecting with more stable inputs.”

This is a management mindset problem — not just a purchasing issue.

Strong companies:

-

Optimize TCO, not purchase price

-

Select chemicals based on system compatibility

-

Invest in long-term stability

5 Questions to Avoid Costly Chemical Mistakes

For expert consultation and accurate information on the chemical industry, KDCCHEMICAL provides fast and reliable support. Visit kdcchemical.vn or contact our hotline at +84 867 883 818.